Machine Vision

The best technical solutions for machine vision applications.

MACHINE VISION

Machine vision is the technology and methods used to provide imaging-based automatic inspection and analysis for such applications as automatic inspection, process control, and robot guidance, usually in industry. Machine vision technology gives industrial equipment the ability to “see” what it is doing and make rapid decisions based on what it sees. The most common uses of machine vision are visual inspection and defect detection, positioning and measuring parts, and identifying, sorting, and tracking products.

Machine vision uses sensors (cameras), processing hardware and software algorithms to automate complex visual inspection tasks and precisely guide handling equipment during product assembly. Applications include Positioning, Identification, Verification, Measurement, and Flaw Detection. Machine vision brings additional safety and operational benefits by reducing human involvement in a manufacturing process. Moreover, it prevents human contamination of clean rooms and protects human workers from hazardous environments.

Artificial intelligence, specifically machine learning by way of deep learning, is making machine vision technology for automated visual inspection more accessible and capable. Machine vision systems offer important advantages like:-

-

+

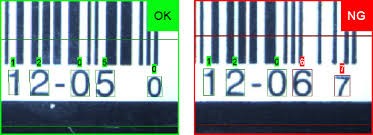

Identification

Quickly identify and read barcodes (1-D), data matrix codes (2-D), direct part marks (DPM), and characters printed on parts, labels, and packages and also basis color, shape and size

-

+

Measurement

Easily validate measurement specifications between two geometrical locations and automatically reject items that fail validation metrics

-

+

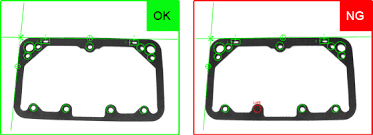

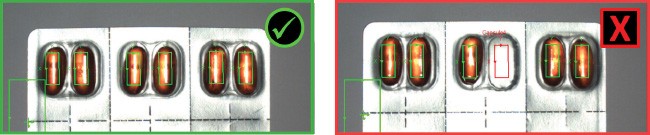

Inspection

Accurately detect defects, contaminants, functional flaws, and other irregularities in manufactured products

Some Applications of machine vision system:

- Absence/Presence detection

- Measurement

- Barcode reading

- Barcode verification

- OCR (Optical character recognition and verification

- Defect detection

- Colour verification

- Pattern matching

How R S helps

We have deployed and integrated machine vision systems in many projects across Pharmaceutical, Automotive, Retail and Electronics verticals using Cognex, Omron and SICK cameras.

These are integrated with high-speed conveyors, customized mountings and pneumatic assemblies to read barcodes, capture product images, test for product quality and absence/presence.

Copyright by @R S Automation Solutions. Development By Givni Pvt. Ltd.