Case Study - Machine Vision

Laser Marking Inspection

-

+

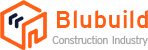

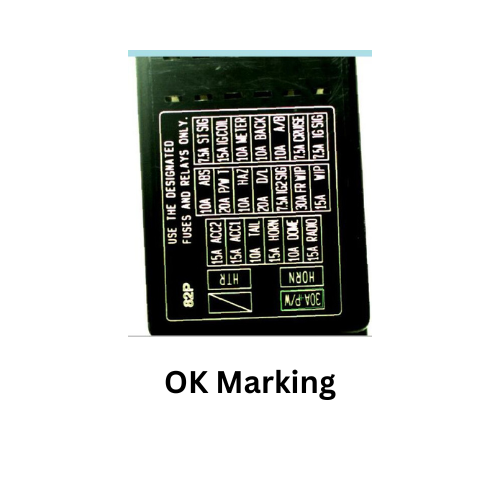

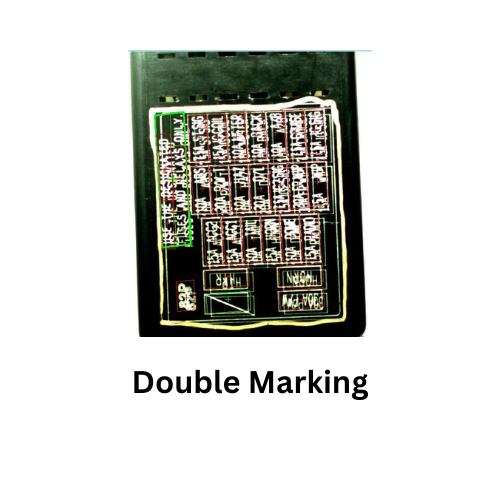

Objective

To check the laser marking on fuse box cover. In this application customer has to check the following defects.

- Marking characters missing

- Double marking

- Marking shift

-

+

Solution

We have given solution for this application using high resolution camera to check the marking on fuse box cover. There are approximate 70 variants which are inspected by machine vision system.

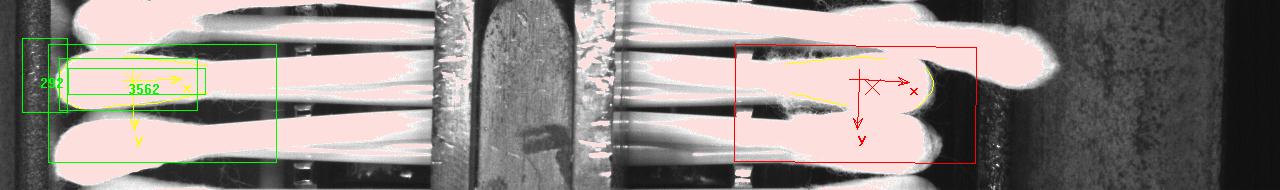

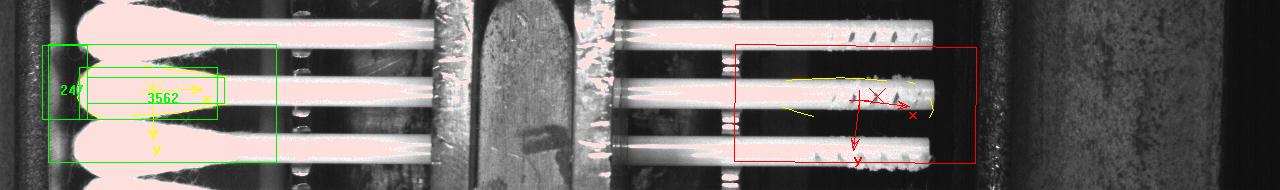

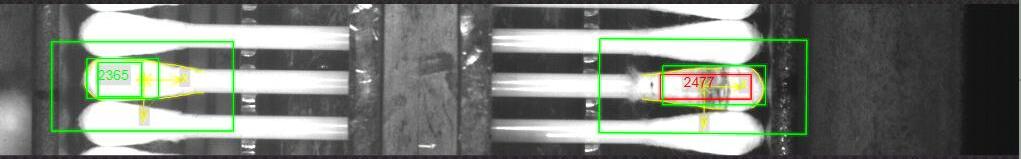

Laser Marking inspection on Bearing(OCR)

-

+

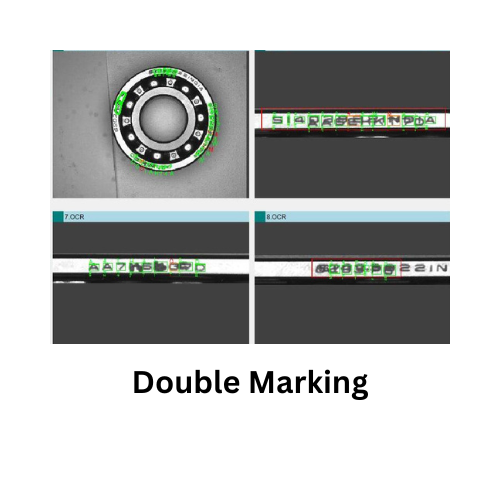

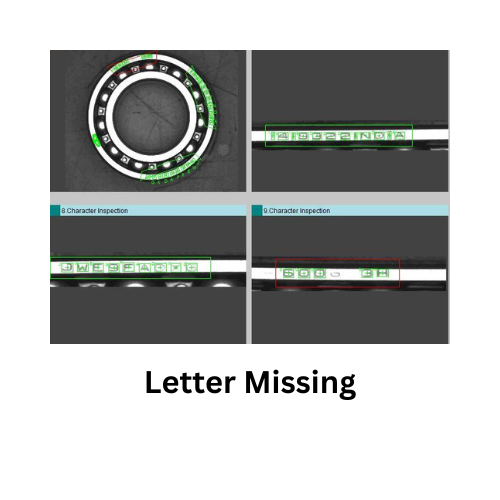

Objective

To identify the following defects of Laser marking on Bearing.

- Single letter missing

- Double marking

- Laser marking shift

-

+

Solution

We have used high resolution camera and special light to check the marking on bearing. 360 degree inspection being done by camera to check the marking defects.

Ear Buds Inspection

-

+

Objective

To check the following defects of buds at rate of 3000 buds/min.

- Empty head

- Deform

- Black spot

-

+

Solution

High speed camera and high intensity light are used for this application to check the defect of Buds at rate of 3000buds/ min.

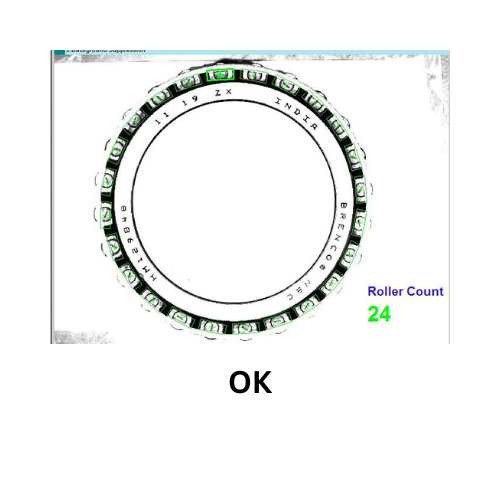

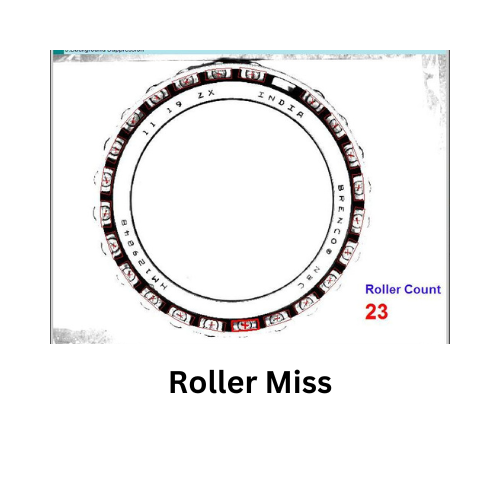

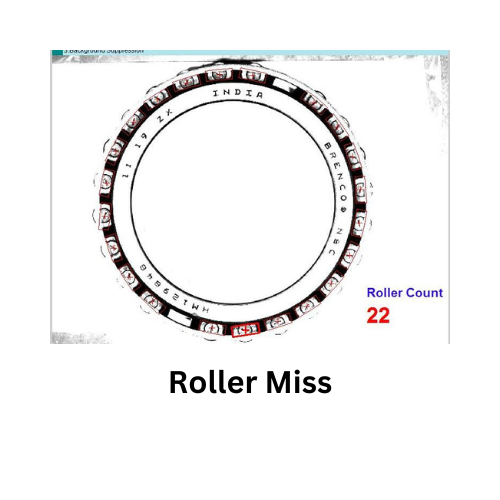

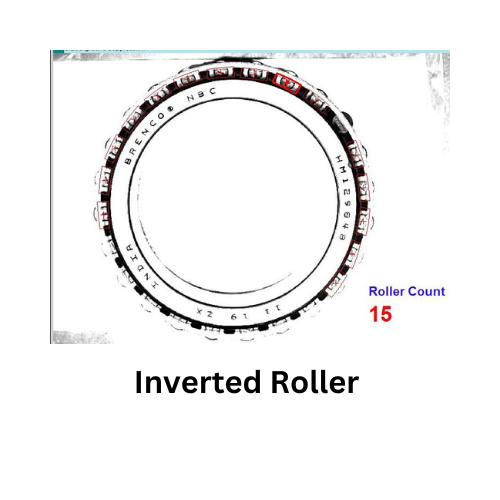

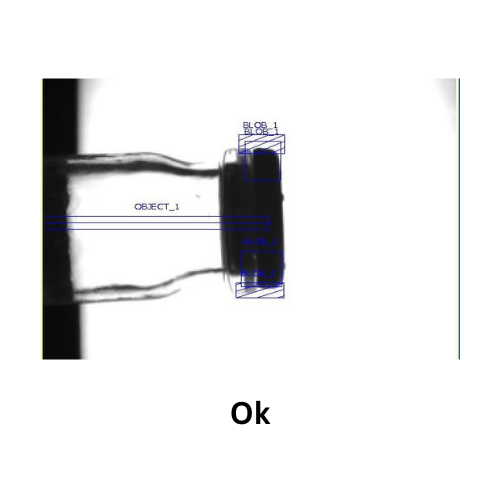

Bearing Roller inspection

-

+

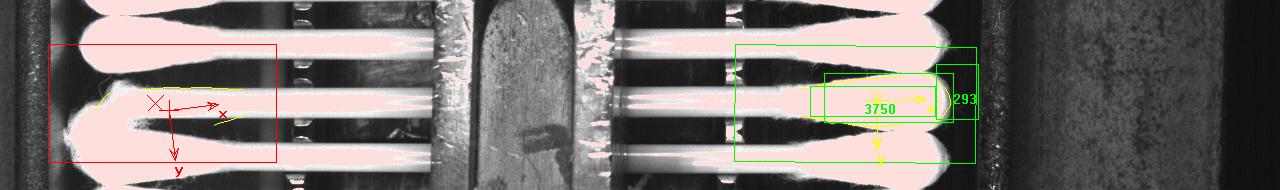

Objective

To check the presence of roller and inverted roller defect. Bearing dia-250 mm

-

+

Solution

High resolution camera and special light used to check the presence of rollers. Camera system checks the roller presence of rollers and gives NG signal for roller missing and inverted roller defect.

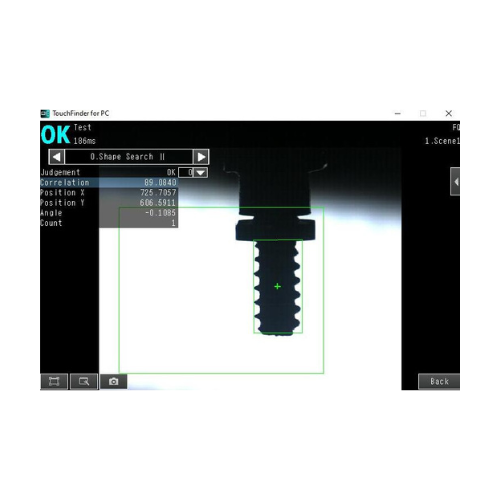

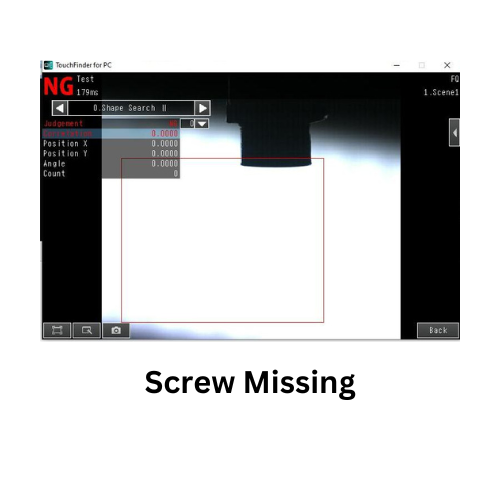

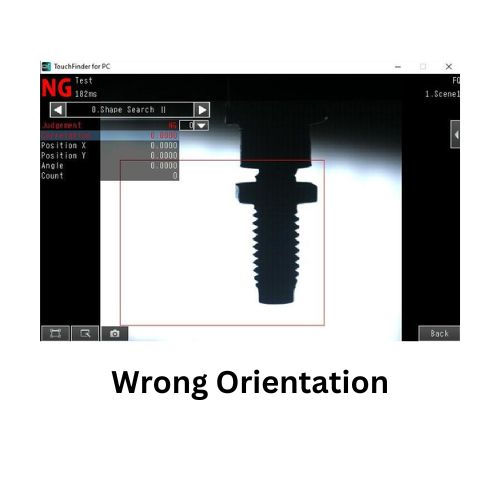

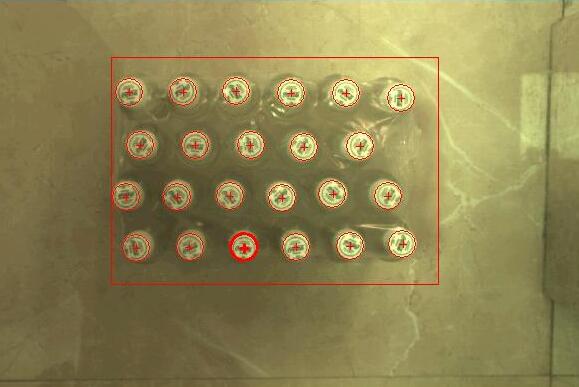

Screw Inspection

-

+

Objective

To verify the presence and correct orientation of screw during tightening process.

-

+

Solution

Smart Camera with special light used to check the presence and orientation of screw during tightening process.

Camera reads the pattern of screw and gives the NG output for missing and wrong orientation conditions.

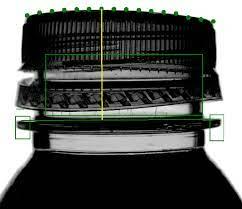

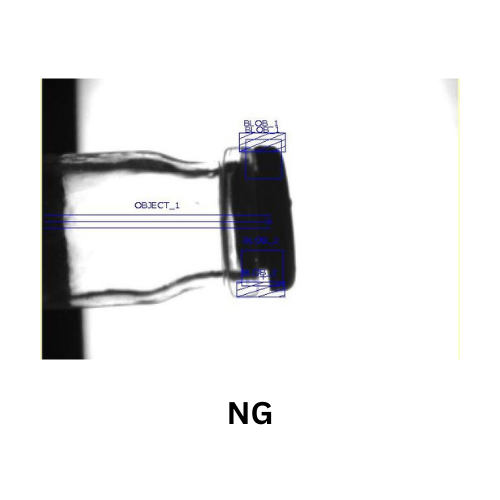

Cap Inspection

-

+

Objective

To verify the cap properly fitted into Vial bottle after filling operation. Line speed is 80 bottles/min

-

+

Solution

Smart Camera and special lED light used for this application to check the proper fitment of cap on Vial bottle after filling process.

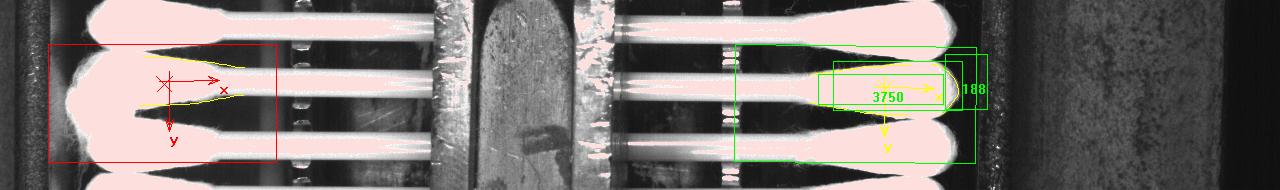

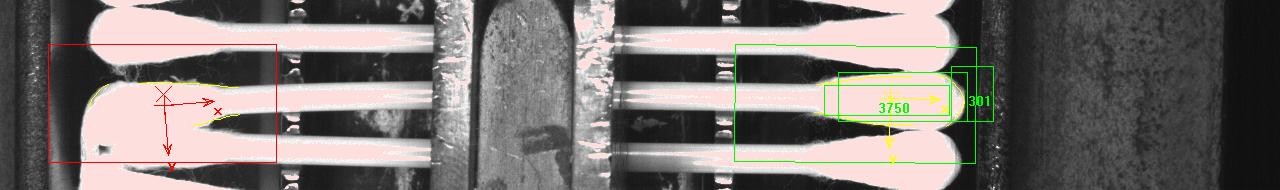

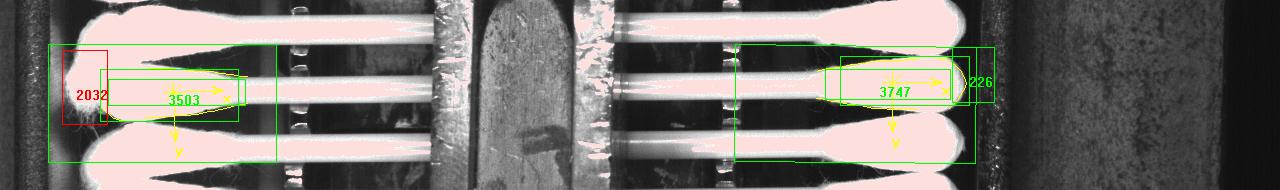

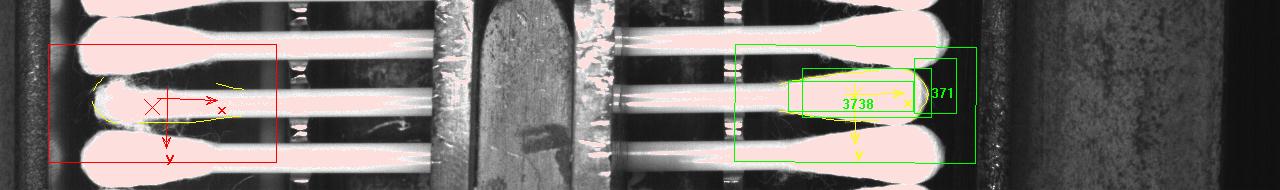

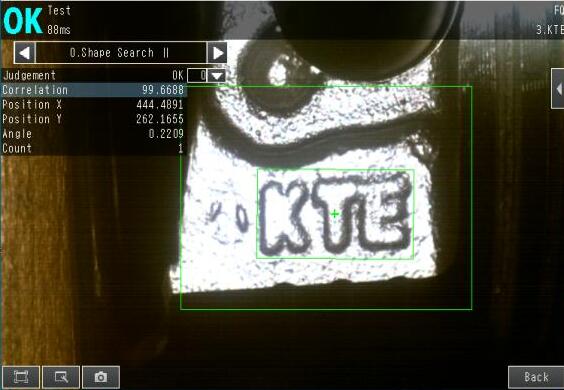

Piston Model Number Verification

-

+

Objective

To verify the correct model running on line to perform Laser marking operation.

-

+

Solution

Smart camera's pattern tool reads the model number as a pattern and checks the every part within a acceptance level. Camera gives NG output for wrong model.

Model KTE Inspection

Model K24A Inspection

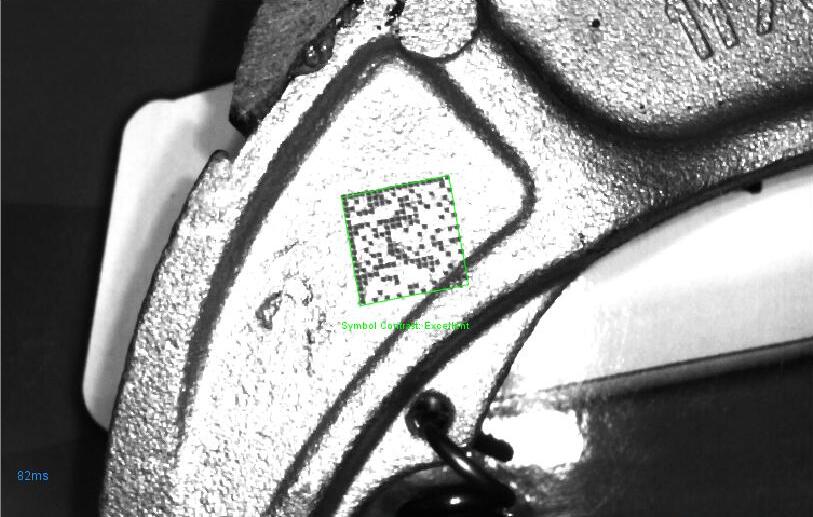

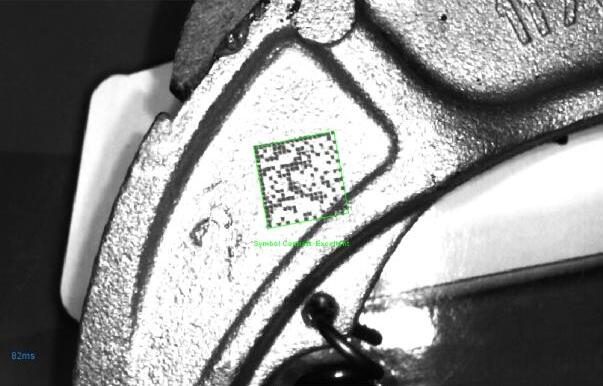

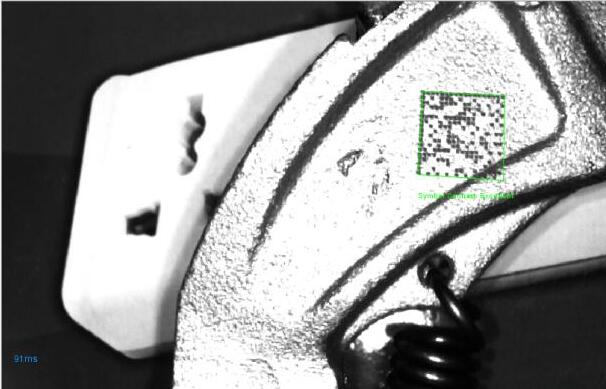

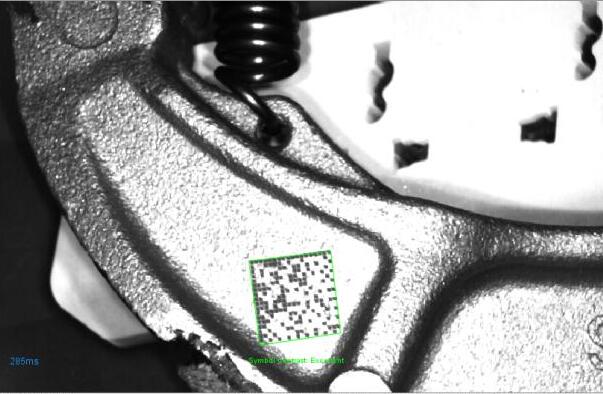

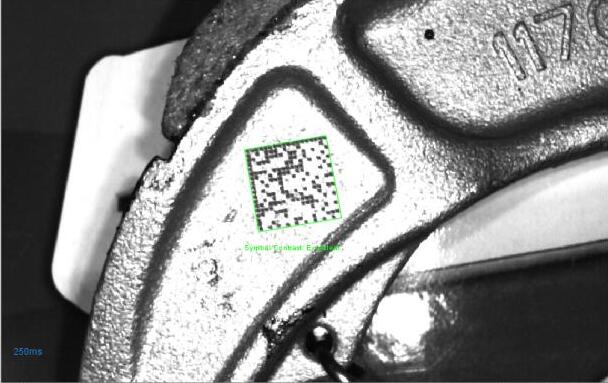

2D Code (DPM) Inspection

-

+

Objective

Application is to read DPM datamatrix code on brake shoe.

-

+

Solution

Fixed mount barcode scanner for 2D code reading used for this application and achieved 100% read rate.

Bottle Counting Inspection

-

+

Objective

To verify the number of bottles in carton.

-

+

Solution

Each Carton and crate must be checkd to ensure the correct number of bottles are present. If the bottle are miss in carton or crate company will incur a loss.

Vision inspection system counts the number of bottle in carton whenever a carton passes the camera on conveyor belt. When the inspection system detects that a box missing one or more bottle, it gives output to reject the wholebox.

Copyright by @R S Automation Solutions. Development By Givni Pvt. Ltd.